FLEET MAINTENANCE O IL STUDY

CURRENT OIL PRACTICES

8 Fleet Maintenance | MAY 2017

Monitoring engine wear through oil

analysis is a quick, non-destructive way

to gauge the health of an engine. Akin

to sending a sample of your blood to

the lab for tests, it reveals information

about the inner workings of an engine.

The information gained from a consistent

oil analysis program can help a fleet:

• Optimize its oil drain interval.

• Increase equipment reliability.

• Minimize unscheduled downtime.

• More precisely track operating

efficiency and maintenance practices.

All of this helps lower total operating costs.

REASONS WHY

Among the reasons for, and

benefits of, oil analysis are:

• Verify when to change oil –

Provides insight about factors

that impact oil change intervals.

• Engine warranty protection –

Can provide support in the

event of a warranty dispute.

• Increased resale value – Some

oil analysis programs have a data

summary analysis feature that

gives a detailed oil analysis history

on a vehicle, adding potential

resale value to the vehicle.

• Preventative maintenance tool –

Alerts maintenance personnel

to hidden or emerging potential

problems or failures which can be

dealt with before they become costly

repairs or a catastrophic failure.

HOW IT WORKS

Oil analysis involves sampling and

analyzing oil for various properties

and materials to monitor wear and

contamination in an engine. Sampling

and analyzing on a regular basis

establishes a baseline of normal wear

and can help indicate when abnormal

wear or contamination is occurring.

Oil inside an engine is in contact with

the mechanical components as wear

metallic trace particles enter the oil.

These particles are so small they remain

in suspension. Products of the engine’s

combustion process also become trapped

in the circulating oil. Any externally caused

contamination also enters the oil.

Consequently, the oil becomes a working

history of the engine. By identifying and

measuring these impurities, an indication

can be gotten of the rate of wear

and of any excessive contamination.

CONSIDERATIONS

Some key considerations for

selecting an oil analysis provider:

• Does the provider offer a

complete array of services?

• Is the provider familiar

with your industry?

• How long has the provider

been in business?

• Does the provider have a reputation

for reliability and quality?

• Does the provider offer

effective training?

• Does the provider have

knowledgeable technical support?

• How user friendly is the oil

analysis program?

• Does the program have additional

data management features, such as

data graphing and summary analysis?

With oil analysis, a sample of an engine’s

motor oil undergoes testing of its physical

properties, as well as identification of

the wear metals it contains. A report is

returned to the user that documents the

results, and in some cases, suggests a

course of action.

It’s a way to gauge

engine health

By David A. Kolman, Editor

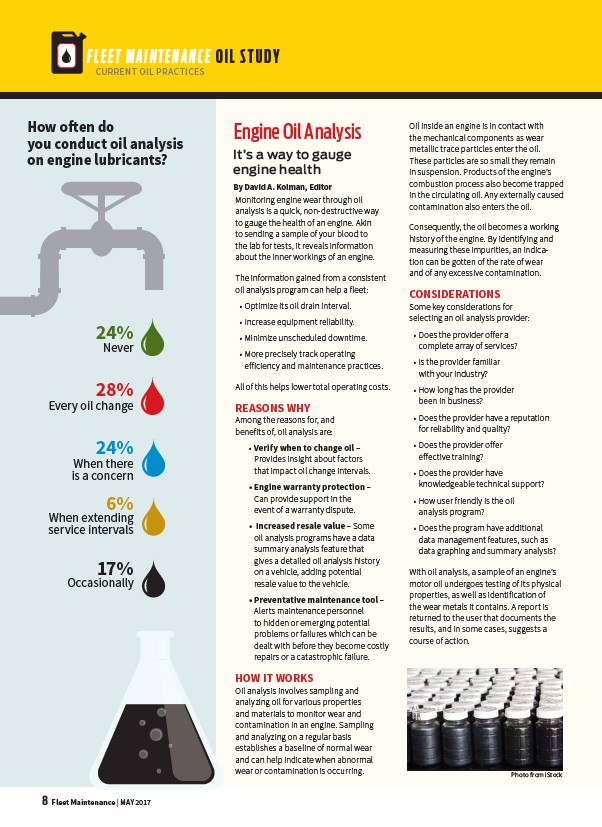

How oft en do

you conduct oil analysis

on engine lubricants?

Engine Oil Analysis

24%

Never

28%

Every oil change

24%

When there

is a concern

6%

When extending

service intervals

17%

Occasionally

Photo from iStock