Gaining an

Edge: Silicone

Edge Graphics

If you have been in an airport recently,

you may have noticed a form of fabric

fi nishing that has been growing in

popularity. Called silicone edge graphics

(SEG), it’s a quick and simple method

to mount fabric-based signage in a

metal frame in a way that’s attractive,

lightweight, and easily swappable.

Basically, you sew a thin silicone strip

– called a welt or a gasket – around the

edge of the printed graphic. The gasket

then fi ts into a groove in a thin aluminum

frame. The graphic is pulled tight,

very closely resembling rigid graphics.

It has become popular for busy public

locations, like airports, since an added

benefi t is that it also absorbs sound.

“If a shop is looking to do wall standoffs

or backlit, SEG is a must,” says Tommy

Martin with Mimaki USA.

The secret to SEG is making sure the

graphic precisely fi ts the frame. Once

you have the template down (SEG kits

come in standard sizes), it’s very easy

to

pop the old graphic out and pop the

new w one

one in. This simplicity eliminates

the need for having professional installers.

ed fo

o

a

aro

e

l

For an added effect, LED lights can

ers.Fo

be used around the edge of the frame

or placed behind the graphic to create a

backlit display.

Mimaki USA. “It’s not used for cutting

very detailed patterns, but mainly for

cross-cutting and other fast, gentle

curve cutting.”

Other cutting tools include:

• Band knife: Th is uses a fl exible, endless

loop blade that remains stationary

while the fabric is moved beneath it.

• Die cutter: Th is uses a metal die

to cut the fabric into specifi c shapes,

like die-cutting used in commercial

printing; it can cut one or several layers

of material.

• Straight blade: Th is is a large (up

to 13 feet), straight, reciprocating blade

cutter with a half-inch-wide blade. It’s

mostly used for cutting several layers

of fabric at high speeds. It can also cut

sharp corners and fi ne detail.

Large cutting tables, such as Esko’s

Kongsberg line, which cut other types of

wide-format and specialty graphics, can

also be used for textiles.

Frayed not

One important consideration in textile

cutting is that when you cut a fabric,

you are exposing the threads that

comprise the fabric. If you have ever

made your own cut-off denim shorts,

you know what can happen: the threads

get more and more frayed. So the edges

need to be sealed.

“If you’re just doing right-angle cuts,

you can cut fabric pretty easily on any

X-Y cutting table,” says Greg Stewart,

22 Wide-Format & Signage June 2017

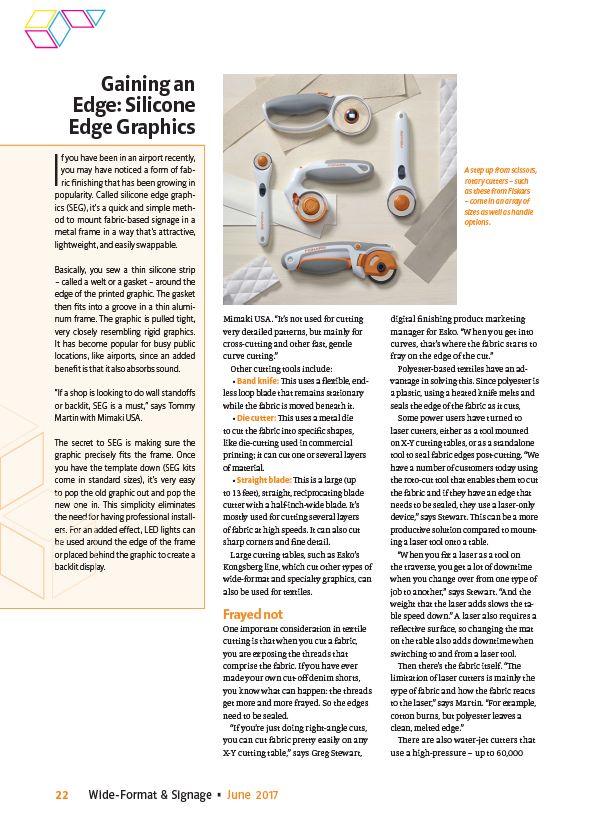

A step up from scissors,

rotary cutters – such

as these from Fiskars

– come in an array of

sizes as well as handle

options.

digital fi nishing product marketing

manager for Esko. “When you get into

curves, that’s where the fabric starts to

fray on the edge of the cut.”

Polyester-based textiles have an advantage

in solving this. Since polyester is

a plastic, using a heated knife melts and

seals the edge of the fabric as it cuts,

Some power users have turned to

laser cutters, either as a tool mounted

on X-Y cutting tables, or as a standalone

tool to seal fabric edges post-cutting. “We

have a number of customers today using

the roto-cut tool that enables them to cut

the fabric and if they have an edge that

needs to be sealed, they use a laser-only

device,” says Stewart. Th is can be a more

productive solution compared to mounting

a laser tool onto a table.

“When you fi x a laser as a tool on

the traverse, you get a lot of downtime

when you change over from one type of

job to another,” says Stewart. “And the

weight that the laser adds slows the table

speed down.” A laser also requires a

refl ective surface, so changing the mat

on the table also adds downtime when

switching to and from a laser tool.

Th en there’s the fabric itself. “Th e

limitation of laser cutters is mainly the

type of fabric and how the fabric reacts

to the laser,” says Martin. “For example,

cotton burns, but polyester leaves a

clean, melted edge.”

Th ere are also water-jet cutters that

use a high-pressure – up to 60,000